Difference between revisions of "3D Printing -- Resin"

| Line 28: | Line 28: | ||

===Training=== | ===Training=== | ||

| − | :'''FDM vs SLA 3D Printing — according to the new Bing''' | + | ::'''FDM vs SLA 3D Printing — according to the new Bing''' |

| − | + | ||

:"FDM and SLA are two different types of 3D printing technologies that use different materials and methods to create parts. FDM stands for fused deposition modeling, and SLA stands for stereolithography. | :"FDM and SLA are two different types of 3D printing technologies that use different materials and methods to create parts. FDM stands for fused deposition modeling, and SLA stands for stereolithography. | ||

| − | + | ||

| − | :Here are some of the main differences between them: | + | ::Here are some of the main differences between them: |

| − | :FDM uses a heated nozzle to extrude melted plastic filament one layer at a time on a build platform. SLA uses a UV laser to cure liquid resin one layer at a time in a resin tank. | + | ::FDM uses a heated nozzle to extrude melted plastic filament one layer at a time on a build platform. SLA uses a UV laser to cure liquid resin one layer at a time in a resin tank. |

| − | + | ||

:FDM can print with a variety of thermoplastic materials, such as ABS, PLA, PETG, and nylon. SLA can print with different types of resin materials, such as standard, engineering, and dental resins. FDM has more color options and similar strength in the X and Y directions than SLA. SLA has better surface finish, detail, and speed than FDM. FDM is cheaper, more user-friendly, and more reliable than SLA. SLA is more expensive, requires more post-processing, and is more sensitive to environmental factors than FDM. FDM is suitable for basic proof-of-concept models, quick and low-cost prototyping, and simple parts that might be machined. SLA is ideal for high-detail parts, molds, patterns, and functional parts that require tight tolerances and smooth surfaces." | :FDM can print with a variety of thermoplastic materials, such as ABS, PLA, PETG, and nylon. SLA can print with different types of resin materials, such as standard, engineering, and dental resins. FDM has more color options and similar strength in the X and Y directions than SLA. SLA has better surface finish, detail, and speed than FDM. FDM is cheaper, more user-friendly, and more reliable than SLA. SLA is more expensive, requires more post-processing, and is more sensitive to environmental factors than FDM. FDM is suitable for basic proof-of-concept models, quick and low-cost prototyping, and simple parts that might be machined. SLA is ideal for high-detail parts, molds, patterns, and functional parts that require tight tolerances and smooth surfaces." | ||

| − | |||

<br> | <br> | ||

:'''[[Intro to SLA 3D Printing]] — class info''' | :'''[[Intro to SLA 3D Printing]] — class info''' | ||

Revision as of 19:07, 18 July 2023

Pikes Peak Makerspace (PPM) is dedicated to supporting our maker community in their creative process by providing shared space, shared tools, software, materials and a knowledge base to turn their ideas into reality.

The 3D Printing Area at PPM consists mostly of Level 2 equipment.

Additional training is required to use our Level 2 equipment.

3D Printing Area hand tools should be marked with orange tape or paint.

Safety First

Members must know the following information:

- In case of emergency, call 911.

- Our physical location is:

- 735 East Pikes Peak Avenue

- Colorado Springs, CO 80903

- use this when ordering pizza or an ambulance

PPM Fire Escape Plan

- Fire Escape Plan maps are posted throughout the Makerspace.

- There are 7 fire extinguishers on the fire escape plan map. Review the PPM Fire Escape Plan for locations.

First Aid

- There is a FIRST AID Supply Cabinet in our Kitchen Area.

- FIRST AID Kits are available in four areas: the Kitchen, Metal Shop, Wood Shop and CNC Room.

Eye Wash Stations

- Emergency Eye & Face Wash Stations are mounted in four areas: the Kitchen, Wood Shop, CNC Room and Vented Room.

Personal Protective Equipment (PPE)

- Wear protective equipment in all Wood and Metal Shop Areas.

- Wear gloves when using Isopropyl Alcohol and other cleaners.

Hazardous Chemicals

- All hazardous chemicals must be stored in the yellow hazardous chemical storage cabinet located in the Vented Room.

- Review the Safety Data Sheet (SDS) information of unknown products before use.

- SDS information is available via the QR code on the hazardous chemical storage cabinet or this spreadsheet.

- Do not bring dangerous chemicals to the makerspace.

- Spray paint, stains, and other approved items must be stored in the hazardous chemical storage cabinet in the Vented Room.

- Please DO NOT paint indoors.

Impairment

- The use of PPM equipment requires you to be alert, attentive, and focused.

- Do not use any PPM work area, or any PPM tools, if you are under the influence of drugs or alcohol.

Classes and Training

New Member Orientation

Area Leader — Chris MacNicol

- To help out in the 3D Printing Area contact the Area Leader on Slack.

Classes

- Pikes Peak Makerspace announces its Upcoming events, including classes, on Meetup

- Our classes are run by dedicated volunteers who generously offer their time and expertise. As a result, class schedules and availability may be subject to change and limitations from time to time.

- Please know that our volunteers are passionate about sharing their knowledge and ensuring a positive learning experience for all. We are grateful for their commitment and dedication to our community. Together, we can create a supportive, cooperative, and understanding community!

Training

- FDM vs SLA 3D Printing — according to the new Bing

- "FDM and SLA are two different types of 3D printing technologies that use different materials and methods to create parts. FDM stands for fused deposition modeling, and SLA stands for stereolithography.

- Here are some of the main differences between them:

- FDM uses a heated nozzle to extrude melted plastic filament one layer at a time on a build platform. SLA uses a UV laser to cure liquid resin one layer at a time in a resin tank.

- FDM can print with a variety of thermoplastic materials, such as ABS, PLA, PETG, and nylon. SLA can print with different types of resin materials, such as standard, engineering, and dental resins. FDM has more color options and similar strength in the X and Y directions than SLA. SLA has better surface finish, detail, and speed than FDM. FDM is cheaper, more user-friendly, and more reliable than SLA. SLA is more expensive, requires more post-processing, and is more sensitive to environmental factors than FDM. FDM is suitable for basic proof-of-concept models, quick and low-cost prototyping, and simple parts that might be machined. SLA is ideal for high-detail parts, molds, patterns, and functional parts that require tight tolerances and smooth surfaces."

- Intro to SLA 3D Printing — class info

- Be sure to log your SLA printing job using the Printer Usage Form.

- Clear the resin trays of the SLA printers carefully and completely to avoid cross-contamination.

For Additional Help

- Use the PPM Slack channel #3d-printing

- List of all PPM Slack channels

- Note that we have a Slack channel (#job-board) for members to post, discuss, or accept job opportunities either within PPM or from the community.

Equipment Lists

3D Printing Equipment

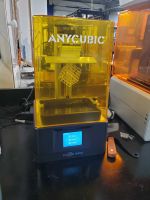

| Picture | Item | Manufacturer | Model Number |

Print Volume |

Upgrades |

| Resin Printer |

Anycubic | Photon Mono 4k | 163 x 102 x 180 mm tall | ||

| Resin Printer |

Anycubic | PHOTON MONO 2K | 163 x 102 x 180 mm tall | magnetic bed | |

Number |

Volume |

3D Printing Equipment — Other

| Picture | Item | Manufacturer |

| Wash and Cure

machine (2.0) |

Anycubic | |

| UV curing box

(6x6x10 inches) |

PPM | |

| Fume Extractor | PACE

8888-0825 | |

3D Printing — Computers

| Picture | Item | Manufacturer/ Model |

CPU | Memory | Storage | System Software |

Application Software |

| computer

(Resin machine), "M-DESIGN-5-G" |

Windows 10 | PrusaSlicer | |||||

Model |

Software |

Software |

Hand Tools

- 3D Printing Area hand tools should be marked with orange tape or paint.

- Return all tools to their proper location after use. This rule applies to all areas of our Makerspace.

Donations Received

Wish List

- Pikes Peak Makerspace is a 501(c)(3) non-profit organization, so we can provide a receipt for any donations you make.

Benefits and Policies

- PPM members enjoy discounts at the following local merchants:

- (bring proof of membership)

| Company | Website | Benefit | Directions to |

| Woodcraft of Colorado Springs | 10% discount | 4438 Austin Bluffs Parkway | |

| CO Lumber Specialties | 10% discount | 3636 Stone Avenue | |

| GENERAL AIR | 10% discount | 3031 N Nevada Ave. | |

| ACE Hardware Uintah Gardens | 10% discount | 1830 W Uintah Street | |

- Map of stores that provide PPM member discounts

- Map of helpful local resources curated by our makers

- At home LightBurn subscriptions can be purchased at a discounted rate for being a PPM member.

- The discount code is saved as a Pinned Message in our 'laser-cutter' channel in Slack.

Equipment Reservations

PPE

- Donate for PPE

- Or, leave donations in a black payment box, or use a QR code.

Materials

Red Tags

- If equipment needs repairs, place a Red Tag on it and report it via the Pikes Peak Makerspace Slack channel #red-tags-issues

- This advises others on the malfunctioning equipment and ensures that actions can be taken to service/repair the equipment.

Scrap and Trash

- Trash day is MONDAY

- Recycling day is MONDAY (96 gallon tote)

- Single Stream Recycling provided by Waste Connections. Paper, cardboard, cans, glass, and one time use plastics.

- Empty recycling and trash into our dumpster at the back (south side) of the building.

- Always leave the space better than you found it.

Related Software

Modeling sw

- Autodesk Fusion 360 — integrated cloud CAD, CAM, CAE, and PCB software

Slicing sw

- Lychee Slicer — (free version) for ANYCUBIC resin printer.

Member Showcase

- For even more member projects, visit our #showcase channel on Slack, or follow our social media links.

See Also

Links to other PPM Wiki pages:

Curated Links

Links to external sites:

- Awesome 3D Printing — on GitHub

Other Fun Stuff

Links to external sites:

Search the PPM Wiki — include Content pages as well as Multimedia.

Contact Us if you cannot find your answer here on our Wiki or if you notice any information that is outdated.