Introduction to the Zing Laser

Revision as of 21:22, 20 May 2015 by Admin (talk | contribs) (Created page with "category:Laser_Cutting {{lvl2|'''This is a level 2 machine! You must go through training before operation!'''}} The Epilog Zing Laser Cutter is a device that uses a high p...")

Template:Lvl2 The Epilog Zing Laser Cutter is a device that uses a high powered laser to etch and cut a variety of materials.

Safety

- The Zing laser modifies the work material using heat. To avoid the risk of file never leave the laser running unattended. Burning down the Makerspace is bad.

- Never run teh Zing without the ventilation fans running. The interaction of the laser and the material generates fumes.

- The laser wavelength is such that the glass cover portects the eyes of the user. Do not attempt to run the laser with the cover open.

![]() NEVER attempt to laser PVC or Vinyl

NEVER attempt to laser PVC or Vinyl

- PVC - Poly Vinyl Chloride.

- The laser will split the molecule and release Chlorine gas which will irritate your eyes, your lungs, the eyes and lungs of ay one else around. It will also attack the finish on the laser optics DO NOT LASER PVC

- Before using the laser, engage brain and associated support structures.

Basic Concepts

- The Zing uses a 30W CO2 laser to interact with materials by heating them. The actual effect is dependent on the material, the laser power setting, the laser speed setting, and the laser resolution setting.

- The beam path originates from a laser generator on the bottom left of the machine and through mirrors, directed to the cutting head

- The mechanics of the machine provide the XYZ translation.

- To pass commands/jobs to the Zing you need to install the appropriate deriver software onto the host computer.

- To the computer, Zing looks like a weird printer.

- The Zing interprets colors and lines into the appropriate laser marking/cutting sequence

Modes of Operation

Raster

- Raster Images are made of pixels. Common examples would be photos or images found online

- The cutter software will take your raster image and convert it into greyscale with each pixel being represented by a dot

- The laser will pulse on and off as it follows these series of dots to create the image

- The cutter achieves fine resolution by adjusting the power of the laser dependent on the darkness/lightness of the dot

Vector

- Vector images are made of points and lines that connect points.

- Can be fully represented by mathematical formulas.

- The laser will use your vector drawing as a path to follow with the laser being continually on

- This method of use is great for cutting out shapes from thin material.

Basic Controls

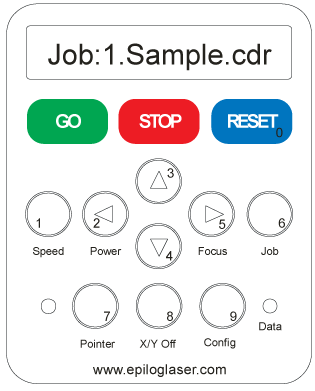

- The Keypad

- To stop the Zing press STOP

- To reset the Zing press RESET (laser turns off, head drives back to starting point)

- To start processing a job, press GO

- To toggle pointer on/off press the pointer button (7)

- To manually set origin:

- Press X/Y Off (8) (this will disconnect the mechanical linkage between the gantry and the stepper motors allowing you to manually move the gantry)

- Open cover and move head to the desired position (BEWARE the optics)

- Press GO

- Press RESET